In 2026, I recommend four top vacuum clamping systems for professional woodworking. The Simple Woodturning Vacuum Manifold offers durability and versatility, while the Laguna CNC Router Creator provides secure hold with modular vacuum pods. The Powertec Vacuum Base Vise adds swivel function for detailed work, and the Vacuum Clamp Pod Kit excels in precision CNC routing. Keep exploring to discover how these systems can boost your workspace efficiency and performance.

Key Takeaways

- Top systems feature durable materials like brass and phenolic resin for long-lasting, reliable vacuum sealing in professional woodworking.

- Compatibility with standard fittings (e.g., 1/4 NPT) ensures seamless integration into existing workshop setups.

- High vacuum strength and adjustable control valves provide secure holding for various workpiece sizes and shapes.

- Easy-to-install, modular designs with clear instructions minimize setup time and enhance workflow efficiency.

- Cost-effective options balance performance, durability, and features suitable for professional woodworking demands.

| Simple Woodturning Vacuum Manifold Kit |  | Best DIY Solution | Material: Brass | Connection Type: 1/4 NPT fittings | Mounting Options: Fittings for vacuum supply | VIEW LATEST PRICE | See Our Full Breakdown |

| LAGUNA CNC ROUTER CREATOR VACUUM HOLD DOWN KIT |  | Professional-Grade | Material: Phenolic resin | Connection Type: 1/4-inch hoses | Mounting Options: Mounting screws, T-nuts | VIEW LATEST PRICE | See Our Full Breakdown |

| POWERTEC Vacuum Base Vise with Swivel Head |  | Versatile Clamp | Material: Die-cast aluminum | Connection Type: Vacuum base with hose connection | Mounting Options: Vacuum base with suction cup | VIEW LATEST PRICE | See Our Full Breakdown |

| Vacuum Clamp Pod Kit for CNC Projects |  | High-Precision Hold | Material: Nylon, brass, PVC foam, stainless steel | Connection Type: Brass fittings, vacuum hose | Mounting Options: T-track, screw-mount, slotted base | VIEW LATEST PRICE | See Our Full Breakdown |

More Details on Our Top Picks

Simple Woodturning Vacuum Manifold Kit

If you’re seeking a reliable yet straightforward vacuum clamping system for woodworking, the Simple Woodturning Vacuum Manifold Kit is an excellent choice. Made of 100% brass, it’s durable and easy to use. It connects your vacuum supply to the lathe chuck, allowing precise control during turning. The kit features a gauge to monitor vacuum levels and a valve to release vacuum quickly for part removal or adjustments. All fittings are 1/4 NPT, so check your pump’s threads beforehand. If you don’t have a vacuum chuck, I recommend purchasing one from us to complete your setup. It’s a simple solution for consistent, secure clamping during your projects.

- Material:Brass

- Connection Type:1/4 NPT fittings

- Mounting Options:Fittings for vacuum supply

- Adjustable Features:Vacuum regulation gauge & valve

- Application Use:Woodturning, vacuum chuck control

- Compatibility:Vacuum pump, vacuum chuck

- Additional Feature:Includes vacuum gauge

- Additional Feature:Brass construction for durability

- Additional Feature:Easy connection fittings

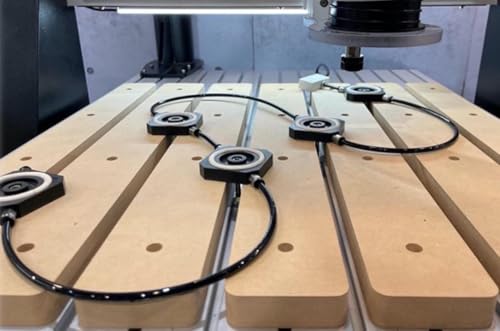

LAGUNA CNC ROUTER CREATOR VACUUM HOLD DOWN KIT

The LAGUNA CNC Router Creator Vacuum Hold Down Kit stands out for its durable phenolic resin vacuum pods, which provide a reliable and secure hold on workpieces during machining. These compact pods feature individual vacuum seals, ensuring strong adhesion across various sizes and shapes. They can be easily arranged to cover large areas by connecting multiple units, and mounting options include MDF spoil boards or aluminum tables with included hardware. Connecting the system is straightforward, using 1/4-inch hoses and fittings to link to the venturi and compressor. Overall, this kit offers a versatile, robust solution for maintaining stability during CNC routing.

- Material:Phenolic resin

- Connection Type:1/4-inch hoses

- Mounting Options:Mounting screws, T-nuts

- Adjustable Features:Adjustable pod arrangement

- Application Use:CNC workpiece hold-downs

- Compatibility:CNC tables, vacuum pump

- Additional Feature:Multiple pods for large areas

- Additional Feature:Phenolic resin pod material

- Additional Feature:Connects multiple units

POWERTEC Vacuum Base Vise with Swivel Head

Designed for versatility and precise positioning, the POWERTEC Vacuum Base Vise with Swivel Head stands out as an ideal choice for hobbyists and small-scale woodworking projects. Constructed from durable die-cast aluminum, it’s lightweight yet resistant to corrosion, ensuring long-lasting use. The rubber suction base provides a secure grip on smooth surfaces like glass and steel, with a locking lever to adjust suction strength. Its 360-degree swivel, along with a 90-degree tilt, allows flexible positioning for various tasks. The V-groove jaw holds round or irregular objects up to 65mm wide, while removable rubber caps protect delicate workpieces from scratches.

- Material:Die-cast aluminum

- Connection Type:Vacuum base with hose connection

- Mounting Options:Vacuum base with suction cup

- Adjustable Features:Locking lever for vacuum, swivel head

- Application Use:Clamping irregular shapes, hobby projects

- Compatibility:Flat, smooth surfaces

- Additional Feature:Swivel and tilt head

- Additional Feature:Rubber suction base

- Additional Feature:Removable rubber jaw caps

Vacuum Clamp Pod Kit for CNC Projects

For professionals seeking precise and unobstructed access during CNC routing, the Vacuum Clamp Pod Kit stands out as an essential tool. It uses a separate vacuum pump to securely hold workpieces, replacing traditional clamps and allowing easy access to edges and surfaces. The kit includes two nylon pods with brass fittings, T-bolts, knobs, a vacuum hose, and gaskets—built for durability and reliability. Its no-arm clamp design minimizes interference, while multiple mounting options speed up setup. Perfect for routing signs, plaques, or any detailed work, this system streamlines workflows and enhances precision in professional CNC projects.

- Material:Nylon, brass, PVC foam, stainless steel

- Connection Type:Brass fittings, vacuum hose

- Mounting Options:T-track, screw-mount, slotted base

- Adjustable Features:Quick activation/release, multiple mounting positions

- Application Use:CNC routing, sign making, plaques

- Compatibility:CNC tables, various workpieces

- Additional Feature:No-arm clamp design

- Additional Feature:Multiple mounting options

- Additional Feature:Stainless steel ball valve

Factors to Consider When Choosing a Vacuum Clamping System for Professional Woodworking

When selecting a vacuum clamping system, I focus on how well it integrates with my existing equipment and whether it offers enough power for secure hold. Ease of installation and durability also matter, along with features that allow me to adjust and control the grip precisely. Considering these factors helps make certain I choose a system that meets my woodworking needs efficiently.

Compatibility With Equipment

Choosing a vacuum clamping system that seamlessly integrates with your existing equipment is vital for reliable and efficient woodworking. First, make sure the fittings match your equipment’s thread size, usually 1/4 NPT, to guarantee proper connections. Check that your vacuum pump’s intake specifications align with the manifold or vacuum generator to prevent weak suction. Also, verify that vacuum seals and fittings are compatible with your CNC or woodworking tables, considering material and mounting options. It’s essential to confirm the vacuum source can generate enough pressure and volume for your workpiece size and material. Lastly, assess whether the vacuum components are designed to work smoothly with your current tooling and fixtures. Proper compatibility minimizes setup issues and maximizes system performance.

Vacuum Power and Strength

Vacuum power and strength directly impact the reliability of your clamping system during woodworking tasks. The vacuum’s ability to generate sufficient holding force depends on the pump’s capacity and how well the system minimizes leaks. Higher vacuum levels, measured in inches of mercury (inHg), allow you to securely clamp heavier or irregularly shaped workpieces. Consistent vacuum pressure is essential to prevent workpieces from slipping during demanding machining or routing. It also needs to counteract cutting forces, vibrations, and accidental impacts. Using properly rated vacuum components like pumps, manifolds, and fittings ensures you achieve and maintain ideal vacuum power. Without adequate strength, even the most advanced system can fail under pressure, risking damage to your workpiece or safety. Prioritizing vacuum power guarantees dependable, secure clamping in all woodworking operations.

Ease of Installation

Installing a vacuum clamping system can seem complex, but selecting one with clearly labeled, standardized fittings makes the process much easier. Look for systems with modular components that connect or disconnect without needing specialized tools, saving time and hassle. Compatibility with existing equipment, like standard 1/4 NPT fittings, reduces the need for adapters and simplifies setup. Clear, step-by-step instructions and visual guides are essential—they help guarantee correct assembly and prevent mistakes. Systems designed with minimal, straightforward connections not only speed up installation but also lower the risk of leaks or connection failures down the line. Choosing a system with these features makes installation more intuitive, less error-prone, and ultimately more efficient for professional woodworking environments.

Material Durability and Quality

Durable materials are essential for ensuring that a vacuum clamping system performs reliably over time. High-quality systems are often made from brass, phenolic resin, or reinforced nylon, which resist wear and maintain sealing integrity through repeated use. The material choice impacts resistance to corrosion and environmental factors, crucial for long-term performance in busy workshops. Using corrosion-resistant materials like aluminum or brass can extend the system’s lifespan, especially in humid or demanding conditions. Material quality directly affects the system’s ability to deliver consistent, reliable vacuum pressure, which is vital for precise woodworking. Investing in robust, high-grade materials ensures your system remains effective, reducing maintenance and preventing leaks that could jeopardize workpiece stability. In the long run, quality materials save you time and money.

Adjustability and Control Features

How can you guarantee precise and adaptable clamping with a vacuum system? The key is in the control features. Adjustable vacuum control valves let me fine-tune suction levels for different materials and workpiece sizes, ensuring ideal grip without damage. Vacuum gauges provide real-time pressure feedback, so I can monitor and maintain the perfect clamping force at all times. Variable venturi or pump speed controls allow me to adjust vacuum strength during operation, enhancing stability and efficiency. Quick-release valves make it easy to release or increase vacuum instantly, streamlining workflow and improving safety. Additionally, multi-zone controls let me independently adjust vacuum levels across various sections of a complex workpiece, offering unparalleled flexibility for intricate woodworking projects. These features are essential for precise, reliable, and flexible clamping.

Cost and Budget Considerations

When choosing a vacuum clamping system for professional woodworking, balancing cost with performance is essential. The initial investment can range from budget-friendly options to high-end setups, impacting overall project expenses. Limited budgets may restrict the number of vacuum pods or manifolds, reducing system scalability for larger or more complex jobs. Cheaper systems might compromise vacuum strength, durability, or ease of use, which can lead to higher long-term maintenance and slower setups. Don’t forget to include costs for accessories like hoses, fittings, and hardware, as these add up. Ultimately, it’s about weighing upfront costs against the potential gains in efficiency and reduced setup time. A well-chosen system offers better value, increasing productivity without breaking the bank.

Frequently Asked Questions

How Often Should Vacuum System Maintenance Be Performed?

I recommend checking and maintaining your vacuum system monthly to guarantee optimal performance. Regular inspections help spot leaks, worn seals, or clogged filters early. If you use your system daily, consider more frequent checks, like weekly. Cleaning filters and verifying gauges keep everything running smoothly. Proper maintenance prevents downtime and extends your equipment’s lifespan, so staying proactive is always better than waiting for issues to arise.

What Safety Precautions Are Necessary When Using Vacuum Clamping Systems?

When using vacuum clamping systems, I always wear safety goggles and gloves to protect my eyes and hands from potential debris or sudden releases. I guarantee the system is properly maintained and checked for leaks before use. I also keep my work area clear of obstructions and never leave the system unattended while operating. These precautions help prevent accidents and ensure a safe, efficient working environment.

Can Vacuum Clamps Be Used for Curved or Irregularly Shaped Surfaces?

Yes, vacuum clamps can be used for curved or irregular surfaces. I’ve found that flexible, pliable sealing membranes help create a good seal around complex shapes. Using adjustable suction levels ensures proper grip without damaging the material. I recommend testing on small sections first to make certain of stability. With the right setup, vacuum clamps are versatile and effective for securely holding curved or uneven surfaces during woodworking projects.

What Is the Maximum Workpiece Size Compatible With These Systems?

I can handle workpieces up to 4 feet by 8 feet, depending on the system. My vacuum clamps are versatile, gripping large panels or irregularly shaped pieces with precision and power. I recommend checking your clamp’s specific capacity, as some systems are designed for smaller projects, while others can manage expansive, elaborate workpieces. Whatever your project size, I’ve got the grip to get it done efficiently.

How Do Vacuum Systems Impact Overall Woodworking Workflow Efficiency?

Vacuum systems really boost my woodworking workflow efficiency by providing quick, secure clamping without the hassle of traditional methods. I can switch between workpieces faster and achieve consistent pressure, which improves precision. Plus, I save time on setup and adjustments, allowing me to focus more on the actual craft. Overall, these systems streamline my process, reduce errors, and help me complete projects more quickly and with better quality.

Conclusion

Choosing the right vacuum clamping system can truly elevate your woodworking projects. It’s funny how the perfect fit seems to find you just when you need it, blending efficiency and precision seamlessly. Whether you’re turning, routing, or CNCing, these top options make the process smoother and more reliable. So, trust your instincts, consider your needs, and let the right vacuum system become your woodworking partner—because great craftsmanship deserves the best hold.